From high-volume lithographic print runs to fast, personalised digital jobs and secure print designed to protect sensitive information, each distinct print process offers unique advantages.

What makes each type of print unique? When should you opt for one over another? And how can combining them improve your communications? With comment from CFH in-house print specialists Julian Smith and Katie Horton, in this blog, we explain the differences, ideal uses, and benefits of lithographic, digital, and security printing - and how they can work together to deliver even better results.

Also known as offset printing, lithographic print is a long-established method that uses plates, ink, and water to create high-quality, professional materials. While often associated with traditional techniques, modern lithographic print is remarkably adaptable - and still widely used.

The process is especially suited to medium and long print runs, where consistency and cost-efficiency are important. It’s often chosen for its ability to reproduce sharp text, smooth colours, and a wide range of finishes.

In lithographic printing, images are transferred from a metal plate onto a rubber blanket, then onto the final surface. The process depends on the principle that oil and water don’t mix - the image area attracts ink, while the rest repels it using a dampening solution.

There are two main types of litho printing:

Because of the skill involved in maintaining ink and water balance, litho presses are typically operated by experienced print professionals. Multi-colour presses may require two or more operators to manage quality and consistency throughout production.

Lithographic print is used across a wide range of sectors and formats, including:

This versatility, along with scalability and wide range of substrates, keeps litho printing relevant in today’s communications mix. Providing an example of our product expertise, CFH Business Development Manager Katie Horton comments: ‘We excel at sustainable print solutions – with CFH offering high-impact lithographic paper wrap printing, that delivers striking designs and powerful shelf presence’.

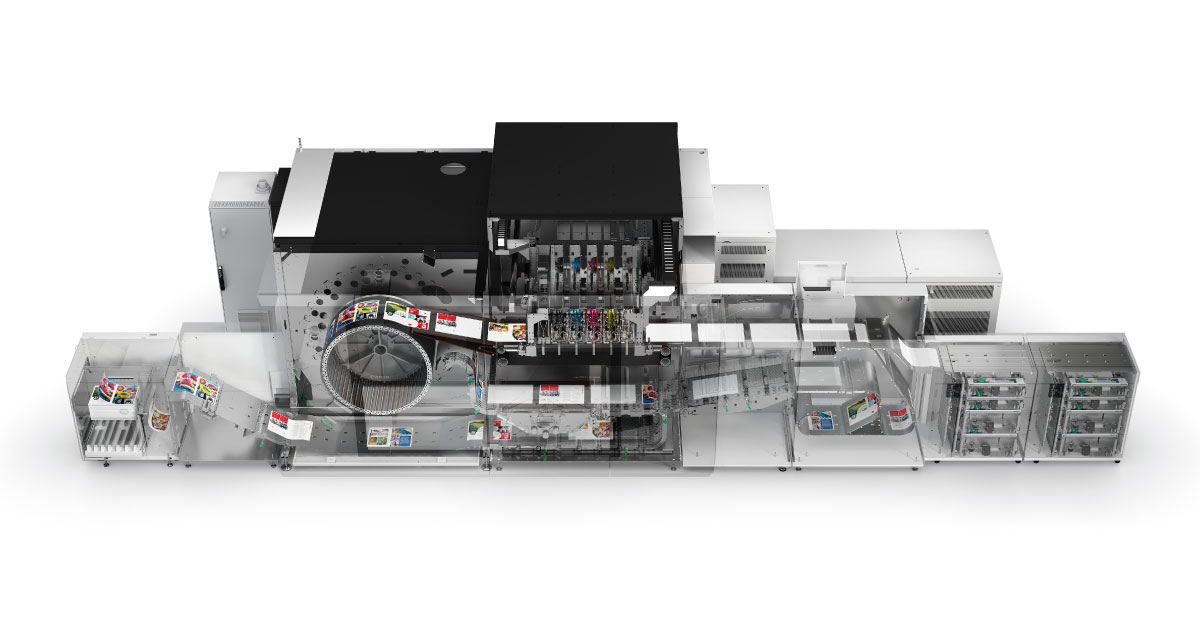

Digital print offers a modern alternative to lithographic printing, one built around flexibility and responsiveness. It enables documents to be produced directly from digital files, without the need for plates, making it ideal for shorter runs and personalised content.

Digital printing came into broader use in the 1990s and has continued to grow thanks to advances in press technology and data-driven communications.

Digital presses typically use either laser (toner-based) or inkjet technology. Data from a digital file - such as a PDF - is processed and sent straight to the printer, which lays down colour and detail in real time.

This process allows for:

It’s a straightforward, efficient option for many everyday communications and can be enhanced with a range of finishes and effects.

Digital printing is often chosen for:

Because there are no plate changes or ink/water balancing, the process is well-suited to fast-paced production.

Security print adds layers of protection to documents that need to be tamper-evident or fraud-resistant. This type of print is used to issue trusted items such as certificates, cheques, PIN mailers, vouchers, ID cards, and secure financial paperwork.

Security print typically involves specialist inks, substrates, and finishes that deter counterfeiting and safeguard sensitive information. Depending on the document and risk level, security features might include:

Accreditation and experience are important in this area. Security printing often requires adherence to recognised standards and thorough handling processes - from design and production to secure dispatch.

In practice, many organisations combine digital, litho, and security printing based on the task at hand. For example, a marketing campaign might use litho print for core materials, digital for personalised follow-ups, and security print for confidential content like PINs or certificates. Each type of print serves a purpose, and by understanding their differences, businesses can get more from their print strategy.

These processes aren’t independent - they’re often used in tandem to deliver smarter outcomes. Lithographic printing, for instance, can produce base stock at scale with features such as integrated labels, cards, or perforations - features that digital printing might not support on its own. Once produced, these litho components can be overprinted digitally to personalise each piece with unique names, addresses, or barcodes.

On the other hand, digital print offers immediacy and flexibility, ideal for quick communications or where content needs to change frequently. It’s common to see digitally printed items inserted alongside litho or security-printed enclosures, forming part of the same outbound communication.

Explaining what makes our service stand out, CFH Specialist Print Development Manager Julian Smith summarises: ‘Quality and customer service ultimately build trust, and we focus on adding value and offering solutions to end user’s specific requirements’.

With a history dating back to 1977, CFH bring decades of experience in delivering high-quality print solutions. From traditional lithographic production to flexible digital printing and secure document handling, we support organisations across a wide range of sectors with dependable, tailored services.

Our print offering is designed to meet the real demands of modern communication, whether you need consistent, high-volume output, personalised mailings, or fraud-resistant materials with added protection.

We operate with a strong foundation in quality, compliance and environmental responsibility, backed by industry-recognised accreditations and a commitment to reducing waste across our processes.

If you’re exploring how print can support your organisation’s goals, we can help you choose the right approach for your project.